Sustainable Recycling of Lithium ion Batteries

2.IPC、Upper computer, lower computer、PLC and other Main electrical components all adopt internationally renowned brands. The human-computer interaction interface is vivid and smooth, and the operation is convenient.

3.Equipped with manual and automatic switching function.

4.The company has established a remote service system based on the Internet of Things to provide strong and timely support for users' after-sales service.

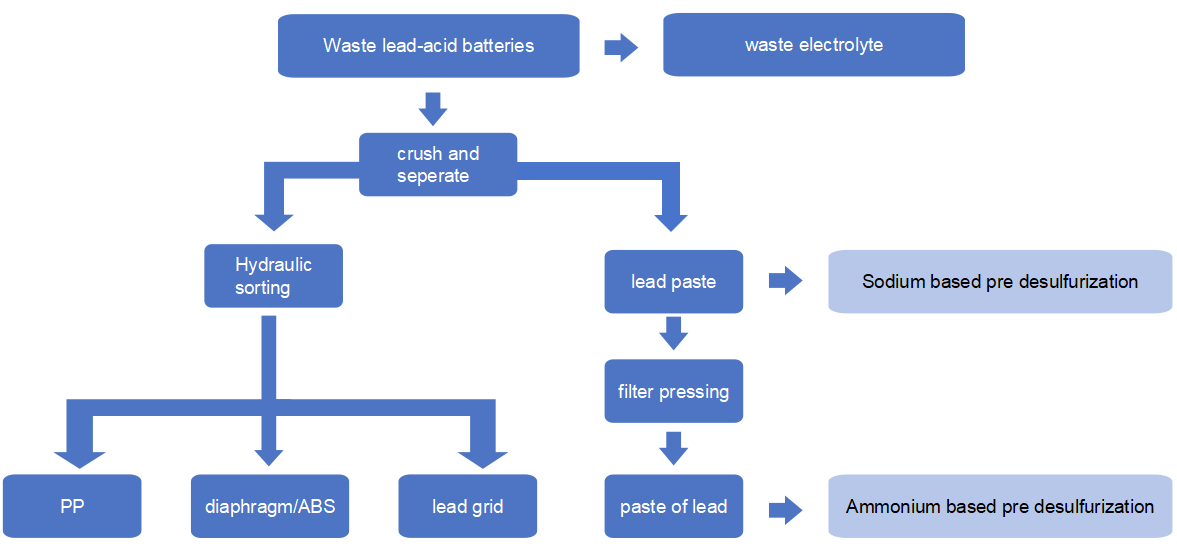

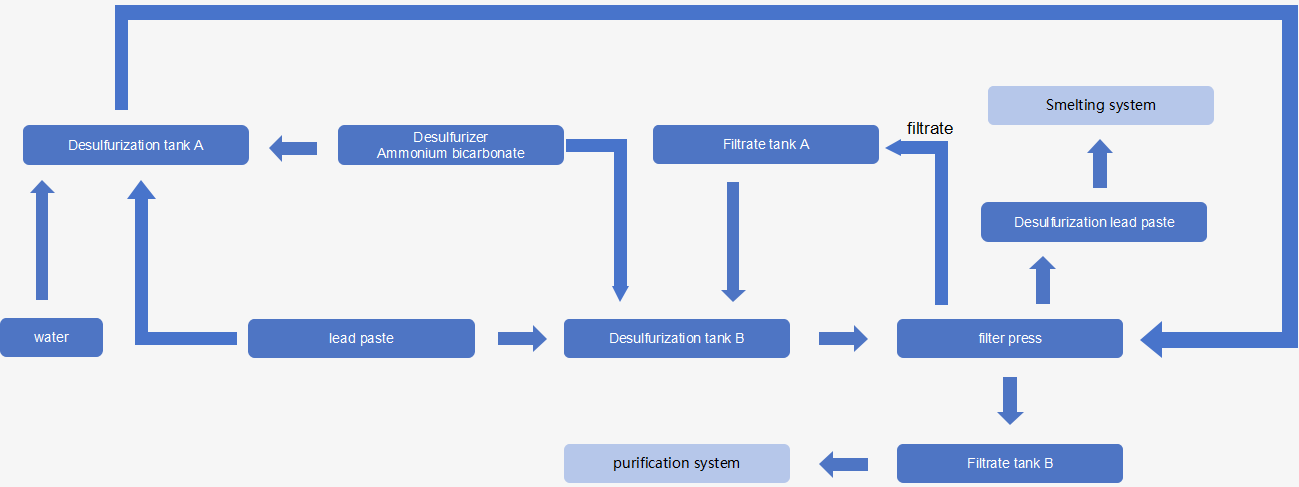

This device is used for desulfurization treatment of lead paste separated from lead-acid batteries. The process includes:

The lead paste enters the pre desulfurization reaction tank A, and desulfurizer (ammonium bicarbonate) is added. At the same time, the mixed lead paste slurry in the tank is subjected to forced desulfurization before returning to the pre desulfurization tank. After the reaction is completed, a filter press is used for solid-liquid separation, and the filter cake (desulfurization lead paste) enters the smelting system; The filtrate (desulfurization filtrate A) enters filtrate tank A. The filtrate A is used as the reaction medium and enters the pre desulfurization reaction tank B. Lead paste and ammonium bicarbonate are added for desulfurization reaction, and the mixed lead paste slurry in the tank is subjected to forced desulfurization before returning to the pre desulfurization tank. After the reaction is completed, a filter press is used for solid-liquid separation, and the filter cake (desulfurization lead paste) enters the smelting system; Filtrate B (desulfurization filtrate B) enters filtrate tank B. The filtrate B (ammonium sulfate) enters the ammonium sulfate purification system.

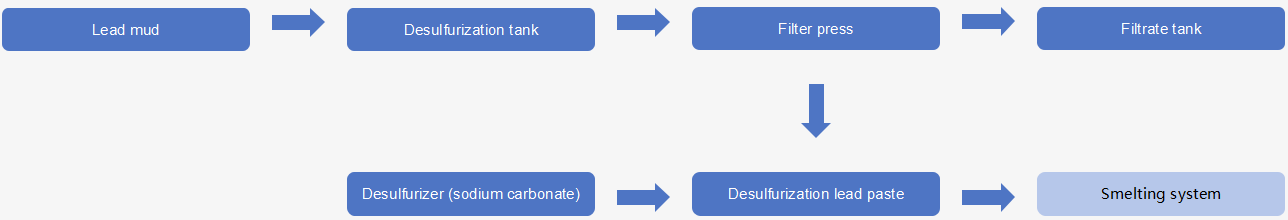

This device is designed for desulfurization treatment of lead sludge obtained from the crushing and separation of lead-acid batteries. The process includes:

Lead mud enters the pre desulfurization tank, reacts with desulfurizer (sodium carbonate), and is thoroughly stirred. At the same time, the mixed lead paste slurry in the tank is subjected to forced desulfurization before returning to the pre desulfurization tank. After the reaction is completed, a filter press is used for solid-liquid separation, and the filter cake (desulfurization lead paste) enters the smelting system; The filtrate (sodium carbonate) enters the filtrate tank.

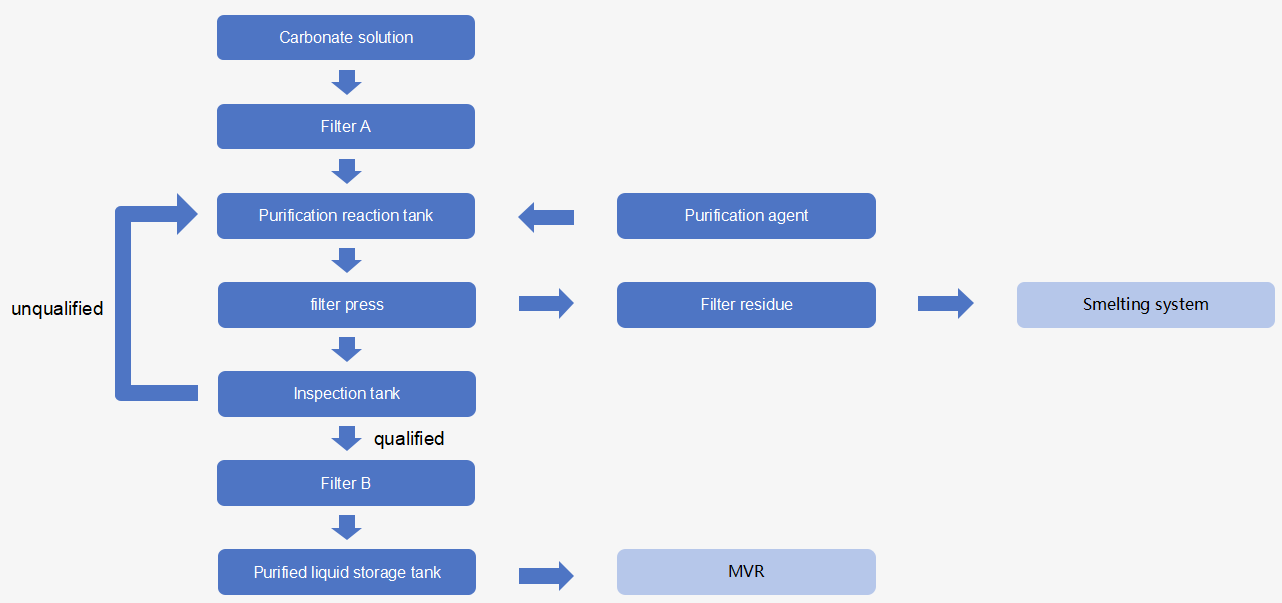

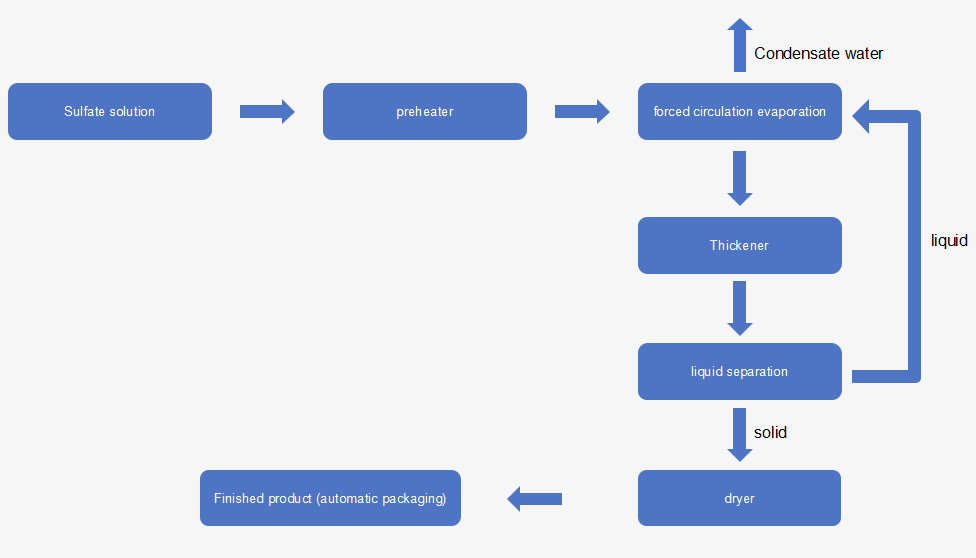

A.Ammonium sulfate solution:25-35%, The heavy metal content in the treated solution is less than 10PPM.

B.Sodium sulfate solution: 16-28%, with a heavy metal content of less than 10 ppm in the treated solution

After complete dehydration through drying equipment, high-purity sulfate products are obtained and sold.